Spartan Power

17 April 2017

This article was originally published in the March issue of COMPRESSORtech2. Get every issue in your inbox/mailbox and access to our digital archives with a free subscription.

Solar Turbines Inc., widely known for its standard gas turbine packages for electric power generation, gas compression and other mechanical drive applications, has added a standardized electric motor-driven compressor solution called the Spartan Electric Motor Drive (EMD). Spartan EMD compressor sets, matched with Solar’s line of centrifugal compressors, are offered in five configurations with ratings from 5000 to 30,000 hp (3729 to 22,371 kW) for a broad range of applications. Electric motor drives are not new to the company. “Solar Turbines already had an installed fleet of over 160 electric motor-driven compressor sets that provided the basis for establishing our standardized EMD product, Spartan,” said Jitendra (Jay) Mistry, international sales manager, EMD compressor business. “We developed this product line because our customers were asking for the same Solar Turbines ‘experience’ that we provide with our turbomachinery equipment.”

The Spartan product has the same power block offering that Solar Turbines offers with its turbomachinery products (e.g., Spartan e130 compared to Titan 130). This nomenclature facilitates sizing of the Spartan EMDs, providing a standardized EMD offering that meets the customer’s specification requirements. Mistry said that the market has responded favorably to the Spartan EMD line, which was introduced in the summer of 2016, with several new Spartan units ordered before the end of the year.

Spartan motors may be induction or synchronous with totally enclosed fan-cooled (TEPV) type enclosures. The patented EMD expanded power range offers full power over a wide speed range. Other motor enclosures and additional balance of plant equipment can be offered to meet the customer’s requirements.

The Spartan line includes a choice of variable-frequency drive (VFD) or variable-speed hydrodynamic drive (VSHD) systems, as well as a constant speed EMD drive when required. “The standardized drive train, optimized with an industry-leading motor/VFD supplier and gearboxes suppliers, provides full rated motor power from 75 to 105% speed,” said Michella Thomas, EMD/Spartan product manager. “The power vs. speed characteristic is similar to a gas turbine with a broader compressor map coverage. The wider speed margin without loss of power enables better gearbox selection with increased flexibility for operating at points other than the original design and restaging the compressor without changing the gearbox. It also avoids larger sizing of the electrical system (MCC, switchgear, etc.).”

Housed in a cabinet that is suitable for installation in a nonhazardous environment, the VFD controls the speed of the motor and is matched to the power required. “It is best suited for applications where more operating flexibility is desired without losing efficiency,” Thomas said. “The VFD features an arc fault resistant design for improved safety, network communication with the Solar PLC, and a robust voltage source inverter design.”

The VSHD is a mechanical means of compressor speed control based on integrating a torque convertor with a gearbox. Depending on the line power available, it sometimes requires a soft start system or pony motor.

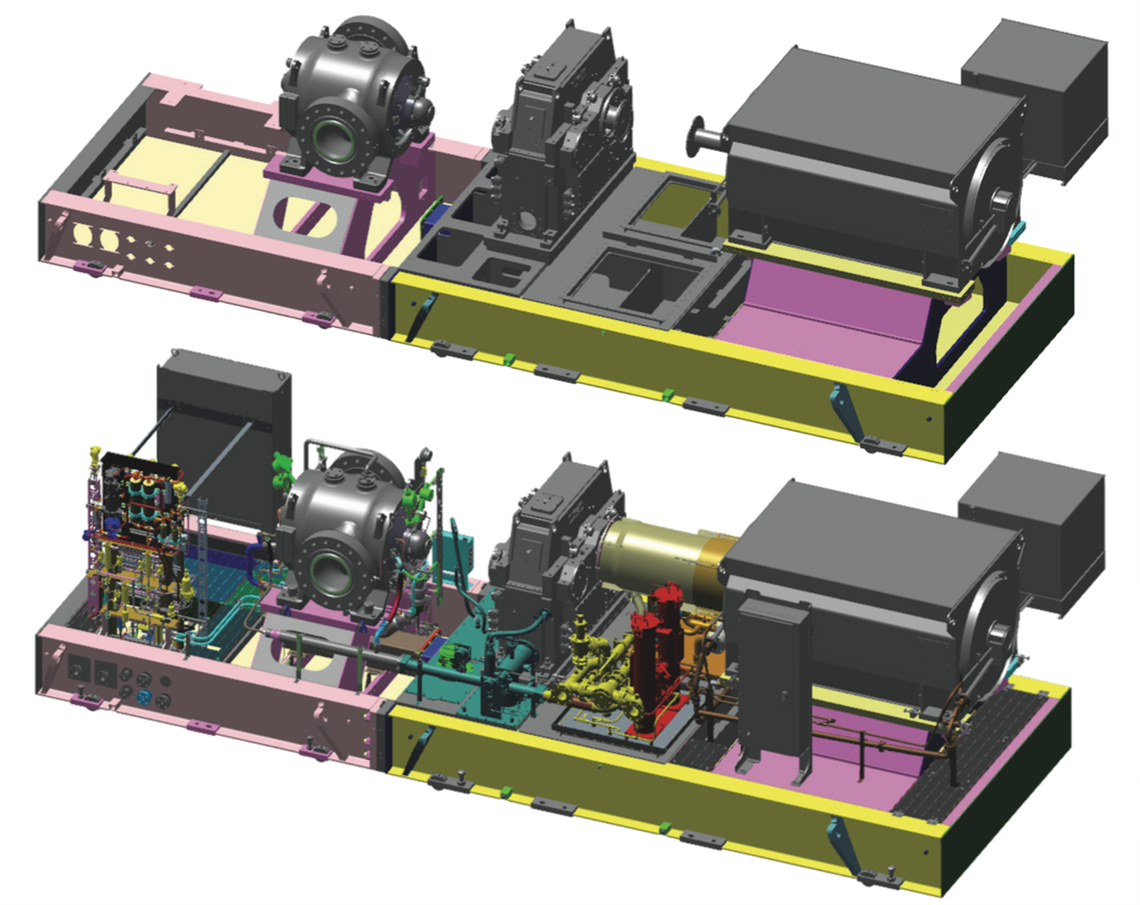

Each Spartan offering is a complete EMD package including input transformer, VFD, filters (if necessary) and motor, which is matched to the appropriate Solar centrifugal compressor package. Key aspects of the package design include an integrated oil system with a gearbox- driven main oil pump and separate electric motor-driven pre/post lube oil pumps. The two-piece structural steel skid (motor and gearbox/compressor and control panel) is designed for transportability and maximum component access for serviceability.

The drive train includes dry, flexible disk low- and high-speed drive couplings with nonsparking coupling guards. Packages also include an on-skid dry gas seal system with gauge panel and an on-skid control panel with an optional off-skid panel. Standard motor instrumentation includes vibration proximeters with advanced monitoring, as well as winding and bearing drain temperature monitors.

The two smallest Spartan EMD models, e50 and e60, are typically matched with a Solar C33 compressor with ratings that range from 5000 to 9000 hp (3730 to 6710 kW). The installed weight of this package with lube oil is 186,550 lb. (84,800 kg), and it measures 32.8 ft. x 11.4 ft. x 9.2 ft. (10 m x 3.5 m x 2.8 m).

The Spartan EMD model e90 is typically matched with a Solar C45 compressor with ratings that range from 9000 to 13,000 hp (6710 to 9690 kW). Installed weight is 350,660 lb. (159,400 kg) and dimensions are 37.8 ft. x 11.8 ft. x 9.8 ft. (11.5 m x 3.6 m x 3.0 m). Model e130 is typically matched with a Solar C65 compressor with ratings from 13,000 to 22,000 hp (9690 to 16,410 kW), having an installed weight of 478,000 lb. (217,300 kg) and dimensions of 40.0 ft. x 13.1 ft. x 10.7 ft. (12.2 m x 4.0 m x 3.3 m). The largest size of the Spartan EMD line is the e250, which is typically matched with a Solar C75 compressor with ratings from 22,000 to 30,000 hp (16,410 to 22,370 kW), with an installed weight of 636,800 lb. (289,500 kg) and dimensions of 46.3ft. x 13.4ft. x 11.7ft.(14.1m x 4.1m x 3.6m). These maximum weights and dimensions exclude the VFD and other off-skid electrical devices.

“Each pre-engineered Spartan EMD package is designed to reduce cost, increase reliability and make installation and startup easier and faster,” Mistry said. “Pre-engineering and standardization ensure design consistency, ready availability of design data and drawings before and after order and installation, and dependable, shorter lead times than custom-designed, motor-driven packages. In fact, the EMD delivery times are consistent with our turbine products.” System design and integration are supported by a staff of dedicated EMD applications, performance, controls, packaging and project management engineers.

“Solar leverages our Six-Sigma based design experience to offer customers comprehensive one-stop solutions for EMD compressor requirements,” Mistry said. “This standard EMD approach also enables faster commissioning and lifetime support. The customer does not have to rely on the EMD supplier for commissioning or be stuck with the inconsistent spare parts availability that occurs with custom motors. Spare parts availability and system integration are also improved.”

Spartan EMD support is provided by Solar as a single point of contact. Annual maintenance programs, recommended spare parts, obsolescence management, failure analysis, tracking and product improvement services are provided. Equipment health management is provided via Solar’s InSight system, backed by its technical support network.

“Our EMD field service representatives (FSR), approximately 25 in number, have been extensively trained for EMD compressor package commissioning and support, including qualifications for medium voltage,” Mistry said. “One FSR can handle the field support of every part of the motor-driven packages. Our objective with this new product line is to provide the same exceptional customer experience offered with our other products throughout the equipment’s entire life cycle. This builds on Solar Turbines’ six decades of experience with more than 15,000 turbomachinery packages installed in more than 100 countries.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

POWER SOURCING GUIDE

The trusted reference and buyer’s guide for 83 years

The original “desktop search engine,” guiding nearly 10,000 users in more than 90 countries it is the primary reference for specifications and details on all the components that go into engine systems.

Visit Now

CONNECT WITH THE TEAM