The evolution of off-highway drivetrains

29 July 2024

Dana navigates a new scenario equipped with new competencies and a closer collaboration with clients.

Jeroen Decleer, senior vice president Off-Highway Drive and Motion Systems at Dana Inc., said the off-highway market has changed a lot and there has been a push to a great extent to move to electric vehicles.

Jeroen Decleer, senior VP Off-Highway Drive and Motion Systems, Dana

Jeroen Decleer, senior VP Off-Highway Drive and Motion Systems, Dana

Now, this is nothing truly unexpected and a trend that all OEMs and component manufacturers in the off-highway space are experiencing. It is important to note, though, how this changed scenario has affected manufacturers of traditional drivetrain components, such as Dana, that have morphed into full system suppliers for the whole powertrain, including components that power and operate the machines.

Decleer confirmed that the trend to electrification is certainly a focus for his company, but it is not the only one. “We have always kept our focus on our traditional drivetrain products, and they remain an active part of our strategy, considering that many vehicles will continue utilizing conventional power sources for quite some time,” he stated.

Additions to the portfolio

Asked about the change in perspective for component manufacturers and how the company has adapted to becoming a supplier of complete powertrains, Decleer said that Dana has worked in the direction of integrating more elements in its product portfolio in order to be successful in certain target markets. This has also been achieved through acquisitions such as Canadian electric drive specialist TM4; integration and application engineering specialist Nordresa; and SME Group, a manufacturer of synchronous reluctance motors and inverters.

The company has added new products and competencies that include electric motors, inverters, control software, battery management systems (working with battery suppliers) and thermal technology. The thermal technology comes from Dana’s Power Technology group, which includes battery cooler plates and bi-polar plates for electrolyzers used in commercial vehicle fuel cells, part of an agreement with Robert Bosch GmbH.

It is not only about products, however. In fact, Decleer described how the Off-Highway Drive and Motion Systems division can leverage years of competencies and expertise from the company’s Commercial Vehicle division, which operates in a market where electrification and other alternative powertrains are well ahead in development and actual adoption.

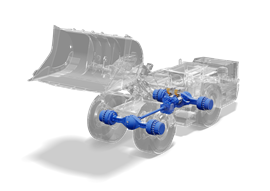

Dana’s electrified driveline for compact construction machinery won the Diesel Progress Summit 2023 Award for New Power Technology of the Year. (Photo: Dana)

Dana’s electrified driveline for compact construction machinery won the Diesel Progress Summit 2023 Award for New Power Technology of the Year. (Photo: Dana)

New trends do not involve only the drive systems of machines. “We have to remember that for any off-highway machine there is a work side, usually with one or more implements to do the actual job,” Decleer said. “Therefore, it is key to manage the flow of energy through the machine’s drivetrain to supply the implements with optimized power. Here, the application know-how is very important to design a system that goes beyond the pure drivetrain.”

Focus on application

According to Decleer, Dana is also growing in terms of application focus, with specific solutions to offer the best powertrain for each segment. Some of these applications are already a given for Dana, which has been delivering for many years to, for example, agriculture, mining, material handling and construction equipment like mini excavators and compact wheel loaders.

Dana is also focusing on turf equipment – a market that it had left a few years ago – and on light material handling machines of the kind you see in logistics, such as lift trucks, AGVs, etc.

“Mining equipment is an especially interesting market for electrification,” said Decleer. “Using electric machines in underground mining has a great potential in abating overall operational costs. According to several sources, ventilation accounts for an average of 40% to 50% of the operational costs in an underground mine. Getting rid of diesel-powered equipment would obviously have an impact on saving part of these significant costs.”

Electric machines in underground mining have great potential to abate overall operational costs. (Photo: Dana)

Electric machines in underground mining have great potential to abate overall operational costs. (Photo: Dana)

Decleer noted that in mining applications, electrification is an interesting proposition for vehicles up to 735-kW power output. “We also look at different vehicle architectures and how they operate in real-world operating conditions, moving from a typical central driveline with transmission and axles to adopting big wheel hubs with electric motors driving them. The control strategy in these cases becomes quite a key element, managing not only the driving and working operations but also functional safety,” he explained.

Sustainable transmission solutions

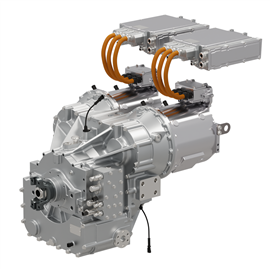

One product that encompasses the move to electrification is Dana’s Spicer eSP502 electric transmission for mid-size power vehicles, providing up to about 240 kW of continuous power output for equipment such as wheel loaders, terminal tractors, material handling machinery, forestry equipment and underground mining vehicles.

“The development of this transmission utilized a modular approach so that it can be used for different applications, including niche segments and even commercial vehicles,” said Decleer.

“It is a two-speed powershift transmission with two Dana TM4 high-voltage electric motors and two inverters plus next-generation control software, all developed in-house. “

By varying the size of the electric motors, the transmission can meet the duty cycle requirements of different machines. It is also available in a one-motor variant.

On the more conventional side, Dana offers the Spicer HVT, a power-split transmission that is a transitional solution on the way to a more sustainable approach. “For those customers and applications not going full electric yet, the HVT is used with a conventional internal combustion engine powertrain but with much lower fuel consumption as the engine is working at a reduced, optimized speed when compared with a powershift transmission,” Decleer noted.

The Spicer eSP502 is a two-speed powershift transmission with two Dana TM4 high-voltage electric motors and two inverters. (Photo: Dana)

The Spicer eSP502 is a two-speed powershift transmission with two Dana TM4 high-voltage electric motors and two inverters. (Photo: Dana)

As part of its re-entry into the turf equipment market, Dana presented a solution for electric zero-turn mowers at Agritechnica 2023. The system features compact Spicer Torque-Hub drives and Dana TM4 electric motors, delivering high torque with no exhaust emissions and lower noise and vibrations while ensuring extended work times and reduced maintenance.

The solution leverages the company’s competence with Dana TM4 permanent magnet and induction motors, power electronics, thermal management, coil winding, outer-rotor topology and motor and inverter control algorithms.

As a transitional solution, Dana offers a new electro-mechanical infinitely variable transmission (EMIVT), a multi-mode driveline system that includes an in-house produced power-split transmission with integrated high-voltage motors, smart lubrication and actuation, a low-voltage motor and inverter to power the pump, plus a driveline controller with proprietary software.

The winner of a 2024 Automotive News PACE Award, the transmission highly differs from traditional transmissions by allowing users to operate in and automatically shift from engine-only, hybrid and battery-only modes. It’s initially being utilized in commercial vehicle market applications such as emergency vehicles and vocational trucks, but it can be adapted for the off-highway and light vehicle markets.

Customer collaboration

One other aspect that has changed in recent years is the collaboration with customers, which nowadays is more intense.

“Collaboration with customers and even with suppliers is much more close-knit than ever before,” said Decleer. “The success in machines’ electrification projects depends much on system integration. This means collaboration starts with studies, design and commissioning but spans throughout the whole vehicle life to include technical support, diagnostics and training of the customer’s personnel that have to deal with an electric system in a safe way, especially when dealing with high-voltage applications.”

Then, there is the aspect concerning sustainability within the companies themselves. “We see requests from the market to comply with sustainability targets. One example is the requirement to utilize green steel that some companies have already made public, as for example, Volvo and Sandvik,” Decleer pointed out.

Dana itself has set climate commitments with the goal of achieving net zero by 2040. Part of the commitment is to reduce Scope 1 and 2 greenhouse gas emissions by 75% by 2030, up from its previously announced goal of 50% by 2030.

There are projects already in the works, for example, an agreement for renewable power purchase for a solar project in Spain that will start in January 2025 and will ultimately offset 100% of Dana’s emissions from purchased electricity in Europe. The company also inaugurated a wind facility in Texas in 2022, which generates approximately 325,000 MWh of renewable electricity annually, offsetting 99.8% of the company’s emissions from purchased electricity in the United States and Canada.

Dana also counts a few on-site renewable energy projects, including a solar array on the campus of its World Headquarters and Technology Center in Maumee, Ohio. The project is expected to supply approximately 30% of the facility’s electricity requirements.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM