Cornerstones of Compression: The evolution of air compressors

January 10, 2025

This continues a series of Cornerstones of Compression corollary articles that provide an historical look at the industries that drove the invention and technological evolution of compressors and that supported the growth and development of the industries that depended on them. This issue continues the evolution of air compressors for mining, construction and manufacturing.

By the beginning of the 20th century, compressed air was becoming widely used in many mining, construction and manufacturing applications. Many companies became major manufacturers of air compressors, and the technology steadily advanced.

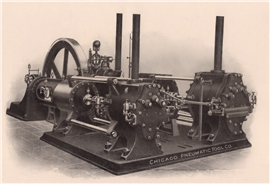

In 1901, the Chicago Pneumatic Tool Company, already a prominent supplier of air operated tools, expanded into the air compressor market by acquiring the Arlington Company, which was an early New Jersey manufacturer of reciprocating air compressors dating back to the early 1890s. After moving Arlington compressor production to its new plant in Franklin, Pennsylvania, Chicago Pneumatic rapidly developed an extensive line of steam-driven and belt-driven compressors. Shown in Fig. 1 is a Chicago Pneumatic Franklin Class C model, which was a Corliss horizontal double cross-compound steam engine-driven two-stage air tandem air compressor.

In 1897, the Claremont, New Hampshire based Sullivan Machinery Company, which began as a manufacturer of machines for quarrying stone, developed new mining products including fans for mine ventilation. After acquiring its major competitor, the M.C. Bulloch Company of Chicago, Illinois, Sullivan devoted much of its energy to developing a line of cross-compound two-stage air compressors. Air had replaced steam for powering rock drills and other construction and mining machinery, and several companies had developed reciprocating air compressors. Sullivan had to purchase compressors from other companies, which was a competitive disadvantage in the construction market that it served. Sullivan delivered its first air compressor in July 1901. The line was an immediate success, and compressors were sold as quickly as they were produced.

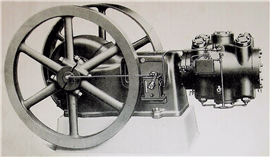

Around the same time, Sullivan built its first steam-driven portable air compressor. It was complete with a boiler and an air receiver, all mounted on a horse-drawn carriage as shown in Fig. 2. Although this was among the first portable air compressors sold, the concept was actually envisioned by Rand Drill Company as early as 1888, combining a straight-line, steam-driven air compressor, vertical boiler and air storage tank on a wooden-wheeled wagon.

Sullivan steam-driven portable air compressor, c.1901.

Sullivan steam-driven portable air compressor, c.1901.

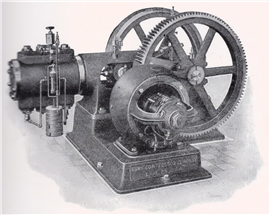

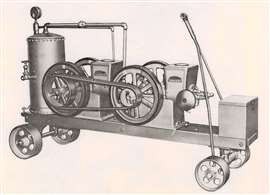

Sullivan also built several series of stationary vertical, horizontal and angle air compressors for use in mines, quarries, foundries and industrial factories. The earliest models were direct steam-driven with simple, compound or cross-compound steam cylinders. The Class WC, shown in Fig. 3, was one of the largest Sullivan air compressors manufactured. It employed Corliss tandem compound steam cylinders driving tandem two-stage air cylinders. Like most early 1900s compressors, it used Corliss suction valves and metal poppet discharge valves. The company also produced several models of belt-driven straight-line single and tandem horizontal compressors as well as angle compressors. The 1918 vintage Sullivan belt driven WG6 compressor shown in Fig. 4 included plate-type valves, which became common just prior to World War I.

Sullivan Class WC, one of its largest air compressors.

Sullivan Class WC, one of its largest air compressors.

Many small companies emerged in the hot bed of industrial production in Western Pennsylvania and nearby regions in Ohio and New York following the oil boom of the late 1800s and early 1900s. These included reciprocating engine and compressor manufacturers that flourished while meeting the needs of the industrial revolution throughout much of the U.S. One such business, the Herron & Bury Manufacturing Company, which started in Erie, Pennsylvania in 1902. Later renamed Bury Compressor Company, within a decade the company was building multiple lines of reciprocating air and gas compressors and vacuum pumps. These included electric motor-driven machines with the motor direct connected with gears as shown in Fig. 5, or with silent chain drive, or mounted directly on the compressor shaft. Bury was an innovative company with a number of early engineering advancements in compressor valves and automatic control.

Sullivan belt-driven WG6 compressor, 1918.

Sullivan belt-driven WG6 compressor, 1918.

From the late 1890s extending well in the Great Depression years, a number of other companies, including Bessemer, Miller, Blaisdell, Bovard & Seyfang and Flickinger, developed horizontal gas engine driven air compressors that fit many niche applications, with one of the most prolific being the supply of compressed air to power converted steam engines that drove well-head crude oil pumps.

Several companies developed smaller air compressors for both stationary and portable applications, such as head stone engraving, painting, spraying and various light construction needs. In 1908, Chris D. Schramm & Son of Philadelphia, Pennsylvania introduced the first commercially successful gasoline engine-drive portable air compressor, shown in Fig. 6. The Gardner Governor Company introduced a small vertical air compressor for portable and stationary applications in 1914. And the Domestic Engine and Pump Company of Shippensburg, Pennsylvania produced its first portable air compressor in 1916. Several other manufacturers soon developed small vertical and vee-type reciprocating compressors that fed the demand for industrial growth.

Bury electric motor-driven air compressor with integral drive gears.

Bury electric motor-driven air compressor with integral drive gears.

The next issue will explore some of the early advances in piston rod packing and compressor valves that enabled higher compressor operating speeds and pressures.

Schramm introduced the first commercially successful gasoline engine-drive portable air compressor, 1918.

Schramm introduced the first commercially successful gasoline engine-drive portable air compressor, 1918.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM