How new scanning tech could help maintain critical infrastructure

November 04, 2024

Marek Helm, CEO of infrastructure tech firm, GScan, on how the company uses muons – naturally occurring and harmless atmospheric radiation – along with AI analysis, to assess the chemical composition and structural integrity of infrastructure, pinpointing any defects in the process to an accuracy of 1mm.

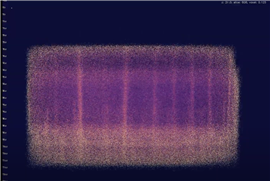

The system testing measurments with muon Flux Infra AI scanners. Picture: Gscan

The system testing measurments with muon Flux Infra AI scanners. Picture: Gscan

Could you explain what GScan does and the practical process for surveying?

GScan analyses the flow of muons, subatomic particles similar to electrons, through solid structures. We have developed technology to pinpoint defects across the built environment and infrastructure down to 1mm accuracy and at a depth of up to 10m.

Our scanners called hodoscopes measure the flow of muons (muon flux) as they pass through an asset of interest. The scattering and absorption of the muons are then analysed by our machine learning and AI-based software to deliver clear maps of materials and defects.

Exactly what AI analysis does the company use?

GScan’s proprietary scanners measure the muon flux. Muons arrive at sea level with an average flow of about 10,000 particles per square metre per minute. The scanners measure muons as they pass through an asset of interest and the scattering and absorption of the muons are then analysed by GScan’s proprietary machine learning (AI) software, which delivers clear maps of materials and defects. We apply machine learning at every level of the data analysis that makes our approach for hardware modifications flexible and quicker to develop.

Could you talk about some of the customers you have and projects that you have worked on?

We have many projects going on now, but one of the most interesting is called Structures Moonshot, which run together with the UK National Highways, AtkinsRealis, and Jacobs. The project is meant to find the best new technologies to assess the status of bridges.

Marek Helm, CEO of infrastructure tech firm, Gscan. Image: Gscan

Marek Helm, CEO of infrastructure tech firm, Gscan. Image: Gscan

What are the common themes that you discover when assessing infrastructure?

The climate crisis and changing regulations mean it is more important than ever to maintain critical infrastructure, minimising new construction costs and reducing carbon outputs where possible.

Experts agree that the ‘greenest’ assets are those that are already built. GScan’s technology allows customers to make informed decisions about how to optimise reconstruction effort, capital expenditure, and environmental impact.

Sustaining existing infrastructure potentially saves up to 60% in construction carbon emissions, saving millions of tonnes of carbon, and provides significant reductions in reconstruction costs.

What are the common faults and issues?

Corrosion is a pressing issue in the built environment. Reinforced concrete, one of the most widely used human made materials, is vulnerable to this problem. While bridges are typically designed to last around 70 years, the steel within them can corrode at varying rates. GScan’s technology offers a solution by accurately detecting corroded areas.

For instance, in post-tensioned bridges, the post-tensioning ducts are particularly susceptible to corrosion. GScan’s technology removes doubt by providing asset owners and operators with accurate data about their asset’s integrity. This can save unnecessary decommissioning and enable far greater clarity on the asset’s status, as well as reducing costs.

A scan of a bridge using the technology. Image: Gscan

A scan of a bridge using the technology. Image: Gscan

Is there a success story that you would highlight in terms of expanding the lifespan of a structure?

I mentioned the Structures Moonshot project. It is a joint project between the UK National Highways, AtkinsRealis, and Jacobs. The project is meant to find the best new technologies to assess the status of bridges. GScan has been selected as one of the most promising ones.

Another story is in the nuclear sector, where we scanned two conserved nuclear submarine reactors. Although the main objective was to optimise the decommissioning plan, we also highlighted the integrity of the main structures and the conservation structures.

Where might this technology develop in the future?

Our vision is to develop a fully automated combined hardware and AI system that can identify and assess structural weaknesses in buildings and structures. Our initial focus is on automating the detection of corrosion. Beyond this, we aim to create a predictive modelling framework that leverages our data to forecast future corrosion levels.

This would allow us to not only report current corrosion conditions, but also to estimate future corrosion progression and even develop comprehensive renovation plans for structures like bridges. In near future, we would like our output data to be part of the Building Information Modelling (BIM) framework.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM