Hydrogen economy essential to decarbonization efforts

April 10, 2023

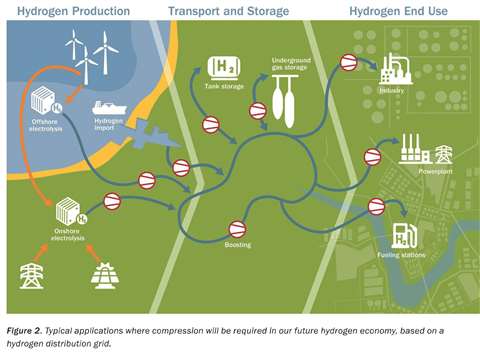

Compression is needed throughout the hydrogen value chain. Illustration: EFRC

Compression is needed throughout the hydrogen value chain. Illustration: EFRC

The hydrogen economy is not an imaginary prospect of some distant utopian future, but increasingly it is a reality, a panel of engineers said in a recent webinar. In response to this, the compression industry has seen a clear increase in orders for hydrogen compressors over the last several months.

“The hydrogen economy is not something for the future anymore. We are witnessing it at this moment,” said Lennert Buijs, a project manager for TNO who spoke at a recent webinar organized by the European Forum for Reciprocating Compressors.

The EFRC recently released a white paper, “Hydrogen Compression: Boosting the Hydrogen Economy,” to discuss the growth of hydrogen compression in Europe. Its recent webinar was held to unveil the main contents of that paper.

The EFRC’s paper gave an overview of the advantages and relative disadvantages of different compression systems used in the hydrogen economy. The organization highlights the existing hydrogen compression technology and the developments in Europe that support the transition towards a green hydrogen economy.

The white paper and the seminar outlined the various types of compressors available for hydrogen compression and the relative advantages and limitations of each. The hydrogen value chain can be divided into three parts: hydrogen production, transportation and storage and hydrogen end use. Compression is needed in each portion of the value chain.

Underground storage

Once produced, hydrogen is then compressed and fed into a transport system. It can be fed into a pipeline, which would also require compression to move the molecules to another location. It can also be transported by trailer, but compression is required here as well – and generally at even higher pressures than pipelines require.

The industry needs compression for storage in tanks or in underground gas storage. In either case, storage can buffer the intermittent nature of hydrogen production and consumption, the paper said.

Hydrogen consumption, the third link of the value chain, may also require compression that meets specific criteria depending on the application. Hydrogen can be used for power generation, as a feedstock, or as a vehicle fuel.

Europe is moving forward with multiple hydrogen projects that are designed to reduce reliance on hydrocarbons. “We see a lot of projects under development right now,” said René Peters, one of the presenters at the recent webinar.

The European Union in its Green Deal sees a significant role for hydrogen and electricity in its future energy system. In the Netherlands, for example, there are about 160 projects that would ultimately produce 12 GW of green hydrogen by 2030, he said.

Europe will also need compression for a growing number of hydrogen refueling stations, which need to provide high purity hydrogen at 350 to 700 bar to fuel personal vehicles or heavy duty trucks. In Germany there are 93 stations in existence and another 50 under development. Netherlands, Belgium, Denmark, Norway and Switzerland also have a growing number of refueling stations.

“We see a large rollout of hydrogen refueling stations in Europe,” Buijs said. “We are rapidly seeing a full coverage of northwest Europe for hydrogen fuel cell vehicles and heavy duty trucks.”

Some midstream operators are trying to use salt caverns and depleted gas fields for large scale storage of hydrogen. As much as 250 GW of hydrogen could be stored in salt caverns. “Storage is vital to secure a market. Caverns are needed to supply security of supply,” he said.

R&D trends

The EFRC has noted that many OEMs are investing heavily in research and development for hydrogen applications. There is a trend, for example, to go to increasing outlet pressure, especially for non-lubricated compressors needed for pure hydrogen.

Another trend in research is the reliability after intermittent starts and stops. Manufacturers are trying to improve the reliability of the machines that are not used at a constant rate. Hydrogen refueling stations are a prime example where a compressor would operate while a vehicle is refueled and then shut off when it is full.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM