Cornerstones of Compression: Thomassen gas engine-compressors

March 28, 2023

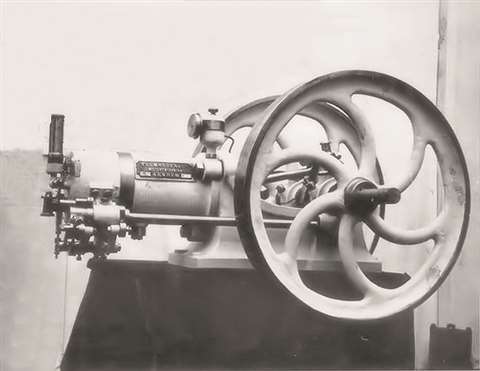

In 1896, Thomassen developed a 0.5 hp (0.4 kW) single-cylinder horizontal gas engine, building 11 of them for Shell to be exported to Indonesia.

In 1896, Thomassen developed a 0.5 hp (0.4 kW) single-cylinder horizontal gas engine, building 11 of them for Shell to be exported to Indonesia.

The history of the company behind the Thomassen engine and compressor brand originated around 1885, when Geurt Thomassen started a forge and repair shop in Arnhem, Netherlands.

The company’s first work related to windmills and railways and, later, steam engine powered machines for sharpening millstones. In 1892, the business moved to a larger building and was named Thomassen & Company.

In 1896, Thomassen developed a 0.5 hp (0.4 kW) single-cylinder horizontal gas engine, building 11 of them for Shell for use in Indonesia. In 1906, with other partners having joined the company, its name became N.V. Machine en Motorenfabriek Thomassen & Company. Although Geurt Thomassen left the company in 1910, it was well established by that time.

A Thomassen diesel engine appeared in 1914, and in 1927, the company secured a diesel engine license from Ricardo that led to the type VO vertical diesel engine in 1929. In 1933, it obtained a license for high-speed diesel engines from Danish company Frichs, which led to the introduction of the Thomassen type 6Fa diesel engine in 1936. Thomassen first applied supercharging to its diesel engines in 1939.

Thomassen’s type 12Na 12-cylinder vee gas engine, was rated at 2100 hp (1566 kW) at 428 rpm.

Thomassen’s type 12Na 12-cylinder vee gas engine, was rated at 2100 hp (1566 kW) at 428 rpm.

In 1922, the company built a big new plant on a 25 acre (10 ha) site with its own rail connection and plenty of room for growth in nearby De Steeg.

However, the cost of the new plant resulted in a pressing debt burden that led to the Batavian Petroleum Company (later Shell) providing financial assistance in return for a substantial stake in the company.

Engine sales declined in the 1930s, and the company branched out into other products for a time, including gas generators to meet the demand for fuel gas for gas engines.

This product was very popular during World War II, when there was no gasoline available in occupied countries. The De Steeg factory was partially looted by the Germans and production stopped entirely in 1944.

After WWII, reconstruction of Europe brought great revival. In 1946, Thomassen produced its first vee-type gas engine as an integral gas engine-compressor. Thomassen began cooperation with Stork for the manufacture of two-cycle diesel engines, with the first Thomassen-Stork type ST two-cycle diesel engine being delivered in 1953.

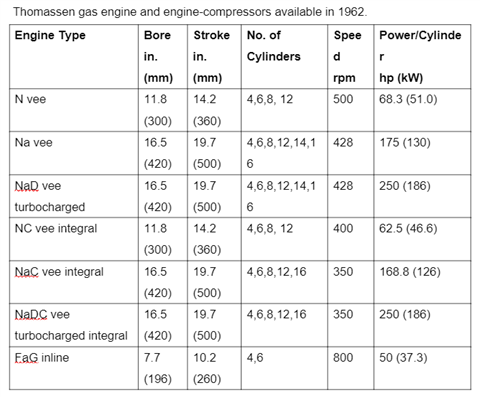

Thomassen gas engine and engine-compressors available in 1962.

Thomassen gas engine and engine-compressors available in 1962.

By 1962, Thomassen had significant lines of gas, diesel and dual fuel engines. It was producing 1500, 1200, 800 and 500 rpm four-cycle diesel engines rated from 160 to 1600 hp (119 to 1193 kW). The company offered four gas engine types and three integral gas engine-compressor types. Some were naturally aspirated and several were turbocharged.

The smallest model was the 7.7 in. (196 mm) bore x 10.2 in. (260 mm) stroke type FaG, built in four- and six-cylinder inline configurations rated at 50 hp (37.3 kW) per cylinder at 800 rpm. All the other types were vee configurations.

The type N was built in four- to twelve-cylinder 11.8 in. (300 mm) bore x 14.2 in. (360 mm) stroke configurations, rated at 68.3 hp (51.0 kW) per cylinder at 500 rpm. The 428 rpm types Na and NaD had 16.5 in. (420 mm) bore x 19.7 in. (500 mm) stroke with four to sixteen cylinders.

The naturally aspirated type Na was rated at 175 hp (130 kW) per cylinder and the turbocharged type NaD was rated at 250 hp (186 kW) per cylinder. Thomassen’s largest gas engine was the 16-cylinder turbocharged type NaD, which was rated at 4000 hp (2983 kW) at 428 rpm.

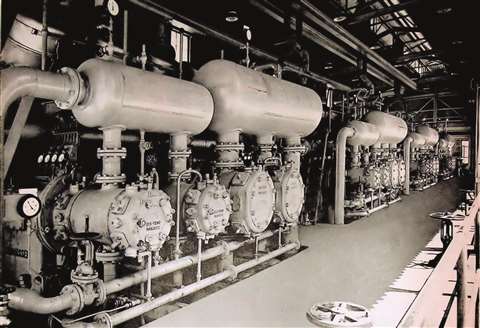

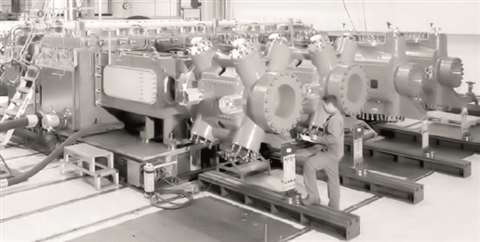

Several Thomassen type 8aNC gas engine-compressors are shown in a compressor station in Geelong, Australia, c. 1960.

Several Thomassen type 8aNC gas engine-compressors are shown in a compressor station in Geelong, Australia, c. 1960.

Thomassen also built three lines of integral gas engine-compressors, types NC, NaC and NaDC. These ran at somewhat lower speeds than the comparable engines, dictated by the allowable compressor piston speed. Thomassen’s diesel engine production ended in 1970, and the last gas engine was built in 1982.

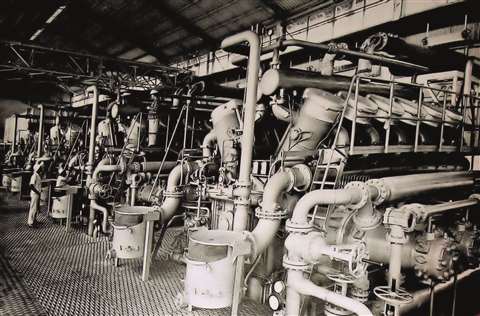

Thomassen’s first compressor was manufactured in 1921 for the Batavian Petroleum Company, and by 1928, 200 compressors had been produced. In 1929, a horizontal gas engine-compressor was introduced. During World War II, Thomassen began secret development of a gas engine-compressor combination. This clandestine effort continued after the war, and resulted in delivery of the first type 4NC gas engine-compressor in 1946.

The first type 8NaC vee gas engine-compressor was produced in 1950, and the company name was changed to N.V. Motorenfabriek Thomassen.

Several Thomassen type 12NaC vee gas engine-compressors in a compressor station in La Paz, Venezuela, c. 1958.

Several Thomassen type 12NaC vee gas engine-compressors in a compressor station in La Paz, Venezuela, c. 1958.

Although there is minimal specific detail about other Thomassen reciprocating compressors, the products were obviously successful, as compressor manufacturing licenses were granted to Nuovo Pignone in Italy in 1954 and to Mitsui Engineering and Shipbuilding in Japan in 1960.

In 1955, Shell sold the majority of its shares in Thomassen and the company obtained licenses to manufacture turbomachinery.

These endeavors were successful as Thomassen built large numbers of centrifugal compressors and steam turbines under license from Elliott, gas turbines under license from Westinghouse, and steam and gas turbines under license from General Electric.

Beginning in 1985, Thomassen began packaging General Electric LM aircraft derivative gas turbines as complete systems. By 1999, all the licenses had ended, but Thomassen continued in the business of servicing steam and gas turbines.

Although production of Thomassen integral gas engine-compressors ended in the early 1980s, the company continued to manufacture large horizontally-opposed compressors, becoming known for highly engineered API 618 compressors for demanding applications.

Thomassen designed and built what were described as the largest API 618 reciprocating compressors ever built in 2015-2016. Six Thomassen eight-throw model C-85 hydrogen compressors were manufactured, each with a rating of 22,260 hp (16,600 kW).

Thomassen designed and built what were described as the largest API 618 reciprocating compressors ever built in 2015-2016. Six Thomassen eight-throw model C-85 hydrogen compressors were manufactured, each with a rating of 22,260 hp (16,600 kW).

In 1999, Thomassen was split into five independent companies. One of them was Thomassen Compression Systems BV that was acquired by the Howden Group in 2011. Under Howden, Thomassen compressors continue to be supplied to the oil and gas industry.

In 2015-2016, as part of a refinery modernization at the Kuwait National Petroleum Company, Thomassen designed and built what were described as the largest API 618 reciprocating compressors ever built.

Six Thomassen eight-throw model C-85 hydrogen compressors were manufactured, each with a rating of 22,260 hp (16,600 kW). In its recent history, Thomassen developed a free-floating piston (“FFP”) system that uses a cushion of process gas to support the piston without lubrication, eliminating rider ring wear. As of 2021, the company indicated that more than 1500 Thomassen reciprocating compressors had been produced in its history.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM